Understanding the Importance of TMT Bar Weight Chart in Construction

Are you planning to construct your

dream home? Or perhaps you're a builder looking for the perfect materials for

your upcoming project. Either way, understanding the importance of TMT bar

weight in construction is crucial. These steel bars play a vital role in

ensuring the structural integrity and durability of any building. But how

exactly does their weight impact the overall strength? And why is it important

to refer to a TMT bar weight chart during construction? In this blog post, we

will dive deep into these questions and explore everything you need to know

about TMT bars and their weight chart. So, let's get started on this

enlightening journey!

What is TMT Bar?

The TMT bars, also known as

Thermo-Mechanically Treated bars, are a type of steel reinforcement bar

extensively used in construction projects. These bars are manufactured through

a specialized process that involves subjecting them to high temperatures

followed by rapid cooling. This unique manufacturing technique imparts

exceptional strength and durability to the bars, making them ideal for

reinforcing concrete structures.

The primary purpose of TMT bars is to provide tensile strength to reinforced

concrete structures. While concrete is excellent at withstanding compression

forces, it lacks the ability to resist tension. By incorporating TMT bars into

the structure, builders can ensure that the load-bearing capacity of the

construction is significantly enhanced.

One distinctive feature of TMT bars is their ribbed surface texture. This

design element helps improve the grip between the bar and surrounding concrete,

preventing slippage or displacement during seismic events or heavy loads.

Another noteworthy advantage of using TMT bars in construction is their

resistance to corrosion. Thanks to their thermo-mechanical treatment process,

these bars exhibit superior resistance against rust and other forms of

deterioration caused by exposure to moisture or atmospheric elements.

In addition to their impressive mechanical properties and corrosion resistance,

TMT bars also offer flexibility in terms of length and diameter options

available in the market. Builders can choose from various sizes based on

specific project requirements without compromising on quality or performance.

TMT bars have revolutionized modern-day construction practices due to their

exceptional strength-to-weight ratio and robustness. Incorporating these

reliable reinforcements ensures structural stability while minimizing

maintenance costs over time.

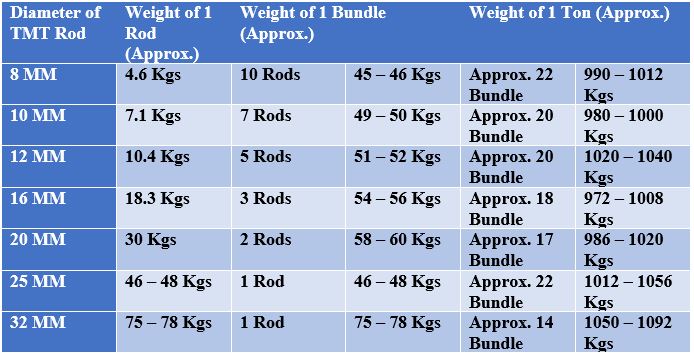

TMT Bar Weight Chart

Diameter

of TMT Rod

|

Weight of

1 Rod (Approx.)

|

Weight of

1 Bundle (Approx.)

|

Weight of

1 Ton (Approx.)

|

||

8 MM

|

4.6

Kgs

|

10

Rods

|

45

– 46 Kgs

|

Approx.

22 Bundle

|

990

– 1012 Kgs

|

10 MM

|

7.1 Kgs

|

7 Rods

|

49 – 50 Kgs

|

Approx. 20

Bundle

|

980 – 1000 Kgs

|

12 MM

|

10.4

Kgs

|

5

Rods

|

51

– 52 Kgs

|

Approx.

20 Bundle

|

1020

– 1040 Kgs

|

16 MM

|

18.3 Kgs

|

3 Rods

|

54 – 56 Kgs

|

Approx. 18

Bundle

|

972 – 1008 Kgs

|

20 MM

|

30

Kgs

|

2

Rods

|

58

– 60 Kgs

|

Approx.

17 Bundle

|

986

– 1020 Kgs

|

25 MM

|

46 – 48 Kgs

|

1 Rod

|

46 – 48 Kgs

|

Approx. 22

Bundle

|

1012 – 1056 Kgs

|

32 MM

|

75

– 78 Kgs

|

1

Rod

|

75

– 78 Kgs

|

Approx.

14 Bundle

|

1050

– 1092 Kgs

|

Why is TMT Bar Weight Important in Construction?

TMT bar weight plays a crucial role

in construction projects. It is important to consider the weight of TMT bars as

it affects various aspects of the construction process.

The weight of TMT bars determines the load-bearing capacity and structural

stability of a building or structure. By using accurate and standardized TMT

bar weights, engineers can ensure that the building can withstand its intended

loads without any compromise on safety.

TMT bar weight affects transportation and handling during construction. Lighter

bars are easier to transport and maneuver on-site, reducing logistics

challenges and saving time. On the other hand, heavier bars may require

specialized equipment for lifting and placement.

Additionally, accurate knowledge of TMT bar weights helps in estimating

material requirements for a project. This enables contractors to plan

effectively by ordering the right quantity of materials needed for

construction, minimizing wastage while ensuring sufficient supply.

Furthermore, understanding TMT bar weights is essential for cost estimation

purposes. The overall cost of a project depends on factors like material

quantities required, including TMT bars. Having precise information about their

weights ensures accurate budgeting and prevents unnecessary expenses.

Considering TMT bar weight is vital in construction due to its impact on

structural integrity, transportation feasibility, material estimation accuracy,

and cost management throughout a project's lifecycle.

Different Types of

TMT Bars

TMT bars, or Thermo-Mechanically

Treated bars, are widely used in construction due to their high strength and

durability. These bars undergo a specialized manufacturing process that

involves heat treatment followed by rapid cooling, resulting in enhanced

properties.

There are several types of TMT bars available in the market, each designed for

specific construction requirements. The most commonly used types include

Fe-415, Fe-500, and Fe-550.

Fe-415 TMT bars have a minimum yield

strength of 415 N/mm2. They are suitable for general construction purposes like

residential buildings and small commercial projects where moderate tensile

strength is required.

Fe-500 TMT bars offer a higher yield

strength of 500 N/mm2. These bars are ideal for heavy-duty structures such as

bridges, flyovers, dams, and industrial buildings that require greater

load-bearing capacity.

Fe-550 TMT bars

provide even higher yield strength at 550 N/mm2. They are specifically designed

for seismic zones with high-risk factors. These bars ensure structural

stability during earthquakes and other natural disasters.

Apart from these standard grades, there are also corrosion-resistant TMT bars

available in the market that offer additional protection against rusting and

atmospheric corrosion.

When selecting the appropriate type of TMT bar for your construction project,

it is crucial to consider factors such as building design specifications,

load-bearing requirements, seismic zone, and durability.

How to Use a TMT

Bar Weight Chart?

When it comes to construction, using

the right materials is crucial for ensuring the strength and durability of a

structure. One such important material is TMT bars. These bars are widely used

in construction projects due to their high tensile strength and flexibility.

To determine the appropriate size and quantity of TMT bars needed for a

project, builders often refer to a TMT bar weight chart. This chart provides

valuable information about the weight of different sizes and grades of TMT

bars.

Using a TMT bar weight chart is fairly simple. First, identify the specific

grade of TMT bar required for your project based on engineering specifications.

Then, refer to the weight chart to find out how much each size of that

particular grade weighs per meter or length.

For example, if you need 10mm diameter TMT bars with a specific grade, you can

easily find its corresponding weight in the chart. This helps builders estimate

the overall weight of TMT bars they will need for their construction project

accurately.

By utilizing this information from the weight chart, builders can ensure that

they procure an adequate amount of TMT bars without any excess or shortage. It

also helps them make informed decisions about reinforcement requirements, which

ultimately contributes to the structural integrity and safety of buildings.

In addition to aiding in estimation purposes during planning stages,

understanding how to use a TMT bar weight chart also proves beneficial during

actual construction work. Builders can keep track of consumed/rejected/broken

steel by referring back regularly while working on-site

Using a TMT bar weight chart plays an essential role in simplifying decision

making related to procurement as well as reinforcing structures effectively

during construction projects.

Conclusion

Understanding the importance of the

TMT bar weight chart in construction is crucial for ensuring the structural

integrity and safety of any building project. TMT bars are widely used in

construction due to their high strength, durability, and flexibility. By

referring to a TMT bar weight chart, builders and engineers can accurately

determine the weight of different types of TMT bars, allowing them to make

informed decisions about the quantity and positioning of these bars.

The use of a TMT bar weight chart helps optimize construction processes by

ensuring that adequate reinforcement is provided while minimizing wastage. It

also assists in calculating accurate estimates for materials required during

construction, ultimately reducing costs.

Different types of TMT bars have varying weights based on their composition and

size. It is important to choose the right type and size of TMT bar according to

specific project requirements. Whether it's earthquake resistance or

load-bearing capacity, understanding these factors will help determine which

type of TMT bar should be used.

To effectively

utilize a TMT bar weight chart, follow these steps:

1. Identify the specific type and size requirement for your project.

2. Locate the corresponding section in the weight chart.

3. Cross-reference with other specifications such as diameter or length if

necessary.

4. Note down the weight per meter or per foot as specified in the chart.

5. Multiply this value by your required length to calculate total weight

needed.

By following these simple steps, you can easily make use of a TMT bar weight

chart for accurate calculations during your construction projects.

In conclusion (without explicitly stating so), having access to an accurateT MT

Bar Weight Chart is essential when planning any construction project involving

reinforced concrete structures. By utilizing this valuable resource effectively

throughout various stages - from estimating material quantities to determining

optimal placement - builders can ensure they meet safety standards while

minimizing wastage and overall costs associated with excessive reinforcements

or insufficient support within concrete structures.

Remember that selecting appropriate types and sizes of TMT bars based on project

requirements is crucial for achieving desired structural strength and

durability. With the right information and understanding, you can ensure your

construction projects are successful and built to last.

Frequently Asked Questions

What is 8 MM TMT Bar Weight?

The weight of an 8mm TMT (Thermo-Mechanically Treated) bar

can also vary based on factors such as the type of steel and the specific

manufacturing standards. As a general estimate, the weight of an 8mm TMT bar is

approximately 0.395 kilograms per meter (kg/m). This value is an approximation

and might differ slightly depending on the manufacturer and the exact

specifications of the TMT bar. Always refer to the manufacturer's documentation

for precise weight information.

What is 10 MM TMT Bar Weight?

The weight of a 10mm TMT bar can vary based on the type of

steel and manufacturing standards. As a rough approximation, the weight of a

10mm TMT bar is approximately 0.617 kilograms per meter (kg/m). However, please

note that this is an estimated value and the actual weight can slightly differ

depending on the manufacturer and the specific specifications of the TMT bar.

For precise weight information, it's recommended to consult the manufacturer's

documentation.

What is 12 MM TMT Bar Weight?

The weight of a 12mm TMT bar can vary based on factors such

as the type of steel used and manufacturing standards. As a general guideline,

the weight of a 12mm TMT bar is approximately 0.888 kilograms per meter (kg/m).

However, please be aware that this is an approximate value and the actual

weight might differ slightly depending on the manufacturer and the exact

specifications of the TMT bar. For precise weight information, it's advisable

to refer to the manufacturer's documentation.

What is 16 MM TMT Bar Weight?

The weight of a 16mm TMT bar can vary based on the specific

type and composition of the steel used in its construction. However, as a

general guideline, the approximate weight of a 16mm TMT bar is around 1.58

kilograms per meter (kg/m). This weight can be slightly different depending on

the manufacturer and the exact specifications of the TMT bar. Keep in mind that

these values are approximate and may vary based on the specific product and

manufacturing standards.

What is 20 MM TMT Bar Weight?

The weight of a 20mm TMT bar can vary based on factors such

as the type of steel and manufacturing standards. As a rough estimate, the

weight of a 20mm TMT bar is approximately 2.469 kilograms per meter (kg/m).

However, please note that this is an estimated value and the actual weight can

slightly differ depending on the manufacturer and the specific specifications

of the TMT bar. For precise weight information, it's recommended to consult the

manufacturer's documentation.

What is 25 MM TMT Bar Weight?

The weight of a 25mm TMT bar can vary based on factors such

as the type of steel and manufacturing standards. As a rough guideline, the

weight of a 25mm TMT bar is approximately 3.853 kilograms per meter (kg/m).

However, please keep in mind that this is an estimated value and the actual

weight might slightly differ depending on the manufacturer and the specific

specifications of the TMT bar. For accurate weight information, it's best to

refer to the manufacturer's documentation.

What is 32 MM TMT Bar Weight?

The weight of a 32mm TMT bar can vary based on factors such

as the type of steel and manufacturing standards. As a rough approximation, the

weight of a 32mm TMT bar is approximately 6.31 kilograms per meter (kg/m).

However, please note that this is an estimated value and the actual weight can

slightly differ depending on the manufacturer and the specific specifications

of the TMT bar. For precise weight information, it's recommended to consult the

manufacturer's documentation.

Comments

Post a Comment